In addition to consumption of human and animal food, pests affect the physical characteristics of food — taste, seed viability and nutritional value. Several investigators have estimated post-harvest food loss as a result of pests at 8 to 25 percent in developed countries, such as the United States, and as high as 70 percent in developing tropical countries. This difference is affected by factors such as climate, higher reproductive potential of the pest population, and inadequate storage and handling.

The most significant factor, however, is the availability and implementation of innovative pest management materials and practices which, though available in the U.S., are only just beginning to be used in developing countries. In addition, the expectations that U.S. consumers have for an abundant and wholesome food supply are a major influence on the demand for effective pest management.

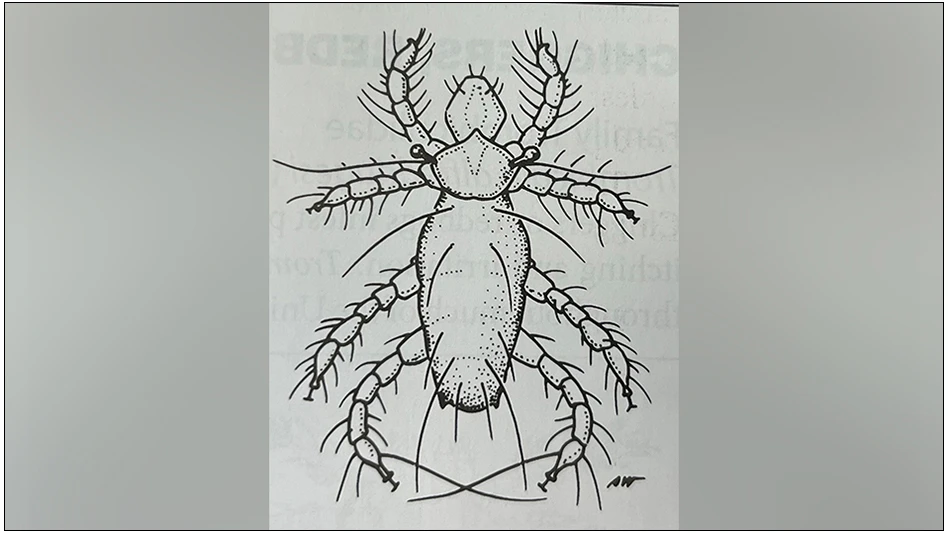

PESTS AND FOOD QUALITY. Pests affect food quality, such as taste, through secretory and excretory products that contaminate foods. For example, confused and red flour beetles impart a distasteful quality to the products they infest. Other health hazards associated with pests in food products include human consumption of living (and fragments of) arthro-pods. For example, the hastasetae (i.e., barbed hairs) associated with dermestid larvae are known to cause severe gastric distress in young children occasionally, and consumption of materials of arthropod origin are known to cause severe allergic problems in sensitive individuals.

For more than 10 years, the Methyl Bromide Technical Options Committee (MBTOC) of the United Nations Environmental Program (UNEP) has been working to develop viable alternatives to methyl bromide, the primary fumigant used in food production. This fumigant is scheduled to be phased out of use in developed countries during the next two years. The challenge to the committee has been to come up with economical and effective pest management strategies that will replace fumigation.

An interesting aspect to the ban on methyl bromide is a provision for exemptions for critical uses. In the Untied States alone a wide range of critical uses have been identified. Nonetheless, it is imperative that alternative products and strategies be developed in the event most, and ultimately all, uses of methyl bromide are lost. The following are pest management options that should be made when looking for alternatives.

Inspection and Identification:

• Information obtained from the homeowner or facility manager often leads to the source of the infestation. The customer should be asked about previous rodent, bird or fly infestations.

• All products and areas, e.g., abandoned rodent or bird nests, which might be infested should be inspected for adults, larvae, webbing, damage and other evidence of infestation.

• Weevil adults within the home indicate the presence of infested whole grain somewhere on the premises, e.g., stored popcorn, dried seed decorations, "bean bags," decorative Indian corn, dried seed-bearing plants and other stored seeds, which are potential sources of infestation.

Sanitation:

• The entire storage area should be vacuumed thoroughly in order to remove flour and other food materials from cracks and crevices.

• Sanitation is important in all grain storage or processing facilities in order to minimize potential breeding sites.

Mechanical and Physical Control:

• All infested materials should be found and removed or destroyed.

• Uninfested products should be placed in insect-proof containers or in a refrigerator or freezer.

• Pest entry should be prevented by repairing all screens, sealing exterior points of entry and keeping exterior doors closed.

• Light traps can be used to monitor and control small populations of flying insect pests.

• Infested stored products also can be sterilized with heat (125°F for one hour), while heat fumigation of entire structures may require 12 to 24 hours.

• Cold (0-5°F) for six days has been used to control stored product pests. Keep in mind home freezers rarely achieve this low temperature, thus much more time is needed to be effective. Cold does not kill all life stages of the pests; eggs are one of the hardest stages to kill.

Biological:

• Pheromone traps have been developed for several species of stored product pests, e.g., Indian meal moths and red flour beetles. They are best used to identify areas of activity rather than to control infestations.

Pesticides:

• Large numbers of adults are easily killed with aerosol applications.

• Liquid and dust formulations should be used to treat cracks, crevices and other voids within cabinets, shelves, pantries and other locations where infestations are found.

• Applications should be made to ensure that all potential harborage areas are well treated.

• Pesticide applications should be supplementary to the elimination of infested material; they never should be used as the sole means of control.

• When necessary, fumigation can be used in large food processing and manufacturing facilities in order to kill all life stages of the pests. Dow AgroSciences is now pursuing the registration of sulfuryl fluoride (Vikane®) as a fumigant for food products.

CONCLUSION. From harvest to consumption, our industry plays a critical role in protecting food products during transportation, storage, processing/manufacturing, distribution, retail sales, customer storage, and, ultimately, consumption. It is unknown at this time what the outcome of these exemptions will be, but rest assured it ain’t over ’til the fat lady sings. Stay tuned for future developments.

The author is technical director of American Pest Management, Takoma Park, Md. He can be reached at 301/891-2600 or rkramer@pctonline.com.

WANT MORE?

Enter your email to receive our newsletters.

Explore the July 2003 Issue

Check out more from this issue and find your next story to read.

Latest from Pest Control Technology

- Target Specialty Products, MGK Partner for Mosquito Webinar

- Cockroach Control and Asthma

- FORSHAW Announces Julie Fogg as Core Account Manager in Georgia, Tennessee

- Envu Introduces Two New Innovations to its Pest Management Portfolio

- Gov. Brian Kemp Proclaimed April as Pest Control Month

- Los Angeles Ranks No. 1 on Terminix's Annual List of Top Mosquito Cities

- Kwik Kill Pest Control's Neerland on PWIPM Involvement, Second-Generation PCO

- NPMA Announces Unlimited Job Postings for Members