The Exacticide PFC from Technicide is an electrostatic, battery-powered duster and fine granule applicator. The Precision Flow Control (PFC) dial can adjust the flow from zero to 1 gram per second at 24 pounds of air pressure. Additionally, the air pressure and flow are adjusted simultaneously. The Exacticide PFC from Technicide is an electrostatic, battery-powered duster and fine granule applicator. The Precision Flow Control (PFC) dial can adjust the flow from zero to 1 gram per second at 24 pounds of air pressure. Additionally, the air pressure and flow are adjusted simultaneously. |

One of Jim Harper’s first memories of being involved with the pest management profession came at the age of 8 when his father had him climb up a ladder, compressed air sprayer in hand, to treat a beehive under the eaves of a house.

When Jim asked his father why he was the one who had to make the climb to get rid of the bees, his dad replied with a straight face, “Well, son, somebody has to hold the ladder.”

With that Harper went about getting rid of that beehive and a lifelong fascination with pest management and how to do it more effectively started for the younger Harper.

“Pest control was all I ever knew,” said Harper, whose father, Vaughn, started Harper Pest Control in 1962 after working with Dewey Pest Control. The elder Harper chose Orange County, Calif., an area at the time that was still heavily populated with strawberry and citrus farms, but that was starting to rapidly become one of the most populous areas in the United States.

Jim Harper started working full time in the family business during the summers at the age of 15 and had to convince his older cousin to serve as his chauffeur since he wasn’t old enough to have a driver’s license. “After one day my cousin decided he needed to get paid for driving me around and I ended up splitting my paycheck with him,” said Harper.

Harper also was responsible for maintaining and repairing the company’s equipment. His prowess was evident early on when he built a truck-mounted power rig that could slide out of the truck, so that the truck could double as a family vehicle.

The company focused primarily on servicing residential accounts in the ever-growing Orange County suburbs with a few commercial accounts sprinkled in. It was his service visits to commercial accounts that encouraged Harper to find a better way to apply product and eventually led him to start Technicide.

Trial and Error. “I went to a seminar where they talked about crack and crevice work in commercial account and I thought there was an opportunity for us to expand the business,” said Harper. “After I started getting into these commercial accounts I realized the application equipment was very archaic and not that effective in getting rid of the insects.”

Harper started tinkering with various delivery systems, identifying what they did well and finding out what were their limitations. He found inspiration after seeing a machine that blew insulation into attics and thought a scaled down version might work for applying dusts into wall voids and other hard-to-get-to locations in an account.

“Everyone was using bulb dusters at the time and there was very little control over the amount of dust they applied, where the dust went and clogging was also a problem,” said Harper.

The limitations in the equipment prevented Harper’s technicians from servicing health-care facilities such as nursing homes and hospitals or food processing/handling accounts where precision application is a must.

|

Technicide Has Gone To The Dogs — Prairie Dogs, That Is! The desire to deliver pest management services in a way that achieves results while respecting the environment is something both pest management professionals and product suppliers work toward day and day out. Since Jim Harper has experience working both sides of the street, he has a unique perspective on what it takes to get the job done. To that end, Harper and Technicide have entered into a unique partnership with the U.S. Forest Service to help get the upper hand on fleas and help save two endangered species. The black-footed ferret and several species of prairie dogs are on the U.S. Fish & Wildlife Service’s endangered or threatened species list in several Western states including Utah, Montana, Colorado and South Dakota. These animals co-exist in the wild with prairie dogs digging tunnels for burrows and ferrets taking up residence after the prairie dogs move out. Both animals were seeing their numbers drastically reduced due in part to severe flea infestations that were taking over their burrows. To help the Forest Service combat the flea problem, Technicide provided the agency with a number of Exacticide Eradication Systems, along with the accompanying training. Forest Service personnel take the units out into the field on ATVs, operating them for up to 12 hours a day as they treat prairie dog burrows. “The Exacticide system allows the Forest Service to apply product deep in the burrow and get to the heart of the flea infestation,” said Harper. “The results have been very positive and the species are making a comeback.” |

In 1988, after much trial and error with various pieces of equipment, Harper decided to take matters into his own hands and design his own equipment, and Technicide was born. The first piece of equipment to leave his workshop was the Nucle-X, an air atomization machine with a dual injector that would allow a technician to apply both a flushing agent and residual insecticide by simply moving their thumb over.

“We discovered while lying on the ground applying a flushing agent in and around large ovens and other equipment in commercial kitchens that we would have to jump up and grab a sprayer to apply a residual spray for knockdown,” said Harper. “This was very inefficient so we designed the dual injector and it saved a lot of time and increased our productivity.”

Harper continued to tinker with various pieces of equipment and in the early 1990s he introduced a duster with similar qualities to his first injection machine. “We found out that by using dust we could get control of the account quicker,” he said.

For example, Harper’s technicians could eliminate an average cockroach problem with two applications of dust over a 10-day span vs. four treatments over a 30-day span with traditional liquid applications.

With his new dust injector providing promising results, Harper shared his invention with other pest management professionals at various meetings and they said, “How do I get one of those?”

A New Career Path. While it wasn’t Harper’s intention to become an equipment manufacturer, the fact he had invested $60,000 of his own money into developing his equipment made the lightbulb go on to share his inventions with paying customers.

Harper said it was difficult wearing two hats since his passion leaned toward the equipment side of the business. There was, however, a silver lining in his struggle to juggle the two worlds — a ready-made, built in research and development division was available in Harper Pest Control.

“The day we finished a piece of equipment I could send it out to the field and have our technicians test it,” said Harper. “The advantage we had when we started selling to other PCOs was that the equipment had been thoroughly field tested not only operationally but in durability as well.”

Harper said his technicians would run the machines hard in the field and they learned where adjustments were needed to improve performance. “We made all the changes before anything hit the market and I think that is why some of our original units are still in service after all these years,” said Harper.

Today, Technicide’s innovative equipment is helping pest management professionals tackle the industry’s current nemesis — bed bugs. The Exacticide Eradication System is being used to treat for these aggressive and fast-travelling pests in a variety of accounts.

“If you look back to the 1940s, dust, especially diatomaceous earth, was used to control bed bugs” said Harper. “Dust is a non-repellent and bed bugs will sit where the dust is applied.”

Harper pointed to a recent bed bug treatment in Texas where diatomaceous earth was applied using the Exacticide system to 2,200 multi-family housing units with severe bed bug infestations and little customer cooperation.

“Over a six-month period we had virtually zero callbacks and the handful that did request follow up service, we went out and inspected, put monitors out and found nothing,” said Harper.

“We have heard from a number of customers who have experienced the same success,” he added.

Harper not only wants to help PMPs control insects, he wants to make technicians’ jobs easier and more efficient. “We want to make average technicians good and good technicians great by using our equipment,” said Harper.

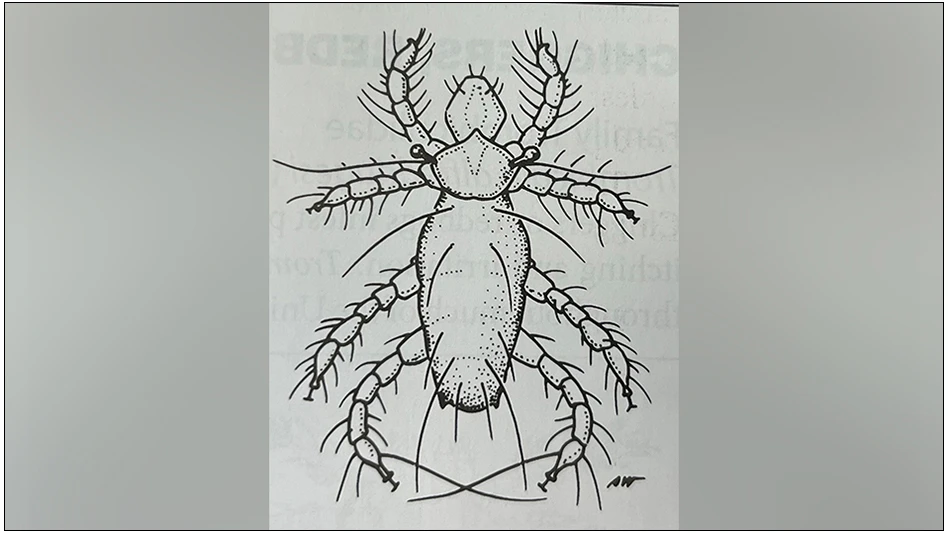

The Exacticide System, an updated version of the original Techni-Duster, treats for a variety of pests including ants, bed bugs, cockroaches, spiders, phorid flies, occasional invaders and stinging insects. It allows technicians to place product in hard-to-reach areas such as behind ovens and large equipment, and under eaves and overhangs using the extension tool. It also has the capability to deliver granule barrier treatments.

Harper says the advantages dusts provide in terms of deep penetration and long residual, combined with the precise application features of the Exacticide system, lets the technician leave the account with confidence that the job was done correctly.

“It allows technicians to make more thorough treatments and its efficiency allows them to do more jobs in a day,” said Harper. “It is also a miser on product since the dust is metered and there is no waste.”

Judy Black, vice president, technical services, Steritech, agreed with Harper’s assessment that the Exacticide System prevents over application of dusts and product waste.

“The system lays down a nice even application of dust and it is easier to learn how to use than traditional bulb dusters,” said Black. “You know you will get the exact amount of product placed in the target area every time.”

Steritech has been a long-time user of Technicide products and was attracted to the brand initially because of its quality engineering and durability. Today, Steritech requires that a unit be placed with every one of their field personnel.

“We use it in virtually any account where we use dusts and primarily to treat against German cockroaches,” said Black. “From restaurants to hotels to health care accounts, wherever crack and crevice work is being done.”

What does the future hold for equipment manufacturers and innovators? According to Harper, there is definitely room for innovation. “If you can think of it, you can create it,” said Harper.

Technicide continues to tinker with new equipment concepts, while looking to make improvements to its current product line. Harper said Technicide is working on a rodent trap that will drastically reduce the amount of time it currently takes to service current units.

Harper said equipment design and delivery has to be greener and sustainable going forward, and has to make technicians more productive and efficient. “Technicians should spend less time treating and more time inspecting and providing preventive services,” he added.

The author is partner of B Communications, www.b-communications.com, an integrated communications/marketing firm specializing in the needs of pest management professionals. He can be reached at jfenner@giemedia.com.

Explore the May 2012 Issue

Check out more from this issue and find your next story to read.

Latest from Pest Control Technology

- Target Specialty Products, MGK Partner for Mosquito Webinar

- Cockroach Control and Asthma

- FORSHAW Announces Julie Fogg as Core Account Manager in Georgia, Tennessee

- Envu Introduces Two New Innovations to its Pest Management Portfolio

- Gov. Brian Kemp Proclaimed April as Pest Control Month

- Los Angeles Ranks No. 1 on Terminix's Annual List of Top Mosquito Cities

- Kwik Kill Pest Control's Neerland on PWIPM Involvement, Second-Generation PCO

- NPMA Announces Unlimited Job Postings for Members