Let’s face it: Bed bugs may be getting the headlines, but in the background roaches are staging a comeback. We have sprayed, fogged, bombed, baited, trapped, heated, fumigated — and still we fight this difficult pest. As roaches have become resistant to current toxicants and government and public pressure for less toxic chemicals increases, we appear poised to lose the battle. Heat treatments are fine, in some places, but usually require evacuation and aren’t always the best answer for the client. Now we have another tool in our pest control toolbox — Cryonite. So just what is Cryonite and how can it improve your roach accounts? Let me show you how Cryonite (new school) in conjunction with spatial/forced monitoring (old school) creates a chemical-free, effective program that can be used anywhere, anytime.

Let’s face it: Bed bugs may be getting the headlines, but in the background roaches are staging a comeback. We have sprayed, fogged, bombed, baited, trapped, heated, fumigated — and still we fight this difficult pest. As roaches have become resistant to current toxicants and government and public pressure for less toxic chemicals increases, we appear poised to lose the battle. Heat treatments are fine, in some places, but usually require evacuation and aren’t always the best answer for the client. Now we have another tool in our pest control toolbox — Cryonite. So just what is Cryonite and how can it improve your roach accounts? Let me show you how Cryonite (new school) in conjunction with spatial/forced monitoring (old school) creates a chemical-free, effective program that can be used anywhere, anytime.

What is Cryonite? Cryonite is a process that turns liquid carbon dioxide (CO2 ) in a tank into carbon dioxide “snow” with an approximate temperature of -108º F. A specially designed and patented gun turns the liquid CO2 into a mixture of small, medium and large frozen particles that are projected out the nozzle into a “snow” that clings to surfaces and slowly evaporates. On contact, it lowers the temperature of the surface immediately and as it warms, the snow evaporates into CO2 gas, leaving no residue.

Although insects have a reputation for surviving extreme cold, they cannot make the transition from room temperature to -108ºF in a matter of seconds. They literally freeze to death. The beauty of Cryonite is that it is easy to use, chemical free and goes anywhere without shutting down operations or evacuating areas. The gun uses ordinary liquid CO2 tanks, which are inexpensive to refill and readily available everywhere. It can be used directly on food preparation areas, areas with sensitive health issues or any other place where chemical contact is a concern.

Since there is no liquid, it can be sprayed into electrical cabinets, outlets, machinery, motors, on textiles, cracks, crevices, along pipes — just about anywhere you can think of. A word of caution about electronics: You can use Cryonite around electronic equipment, however, DO NOT use it in or on electronic components unless you check with the manufacturer and they specifically approve its usage on their equipment.

Since there is no liquid, it can be sprayed into electrical cabinets, outlets, machinery, motors, on textiles, cracks, crevices, along pipes — just about anywhere you can think of. A word of caution about electronics: You can use Cryonite around electronic equipment, however, DO NOT use it in or on electronic components unless you check with the manufacturer and they specifically approve its usage on their equipment.

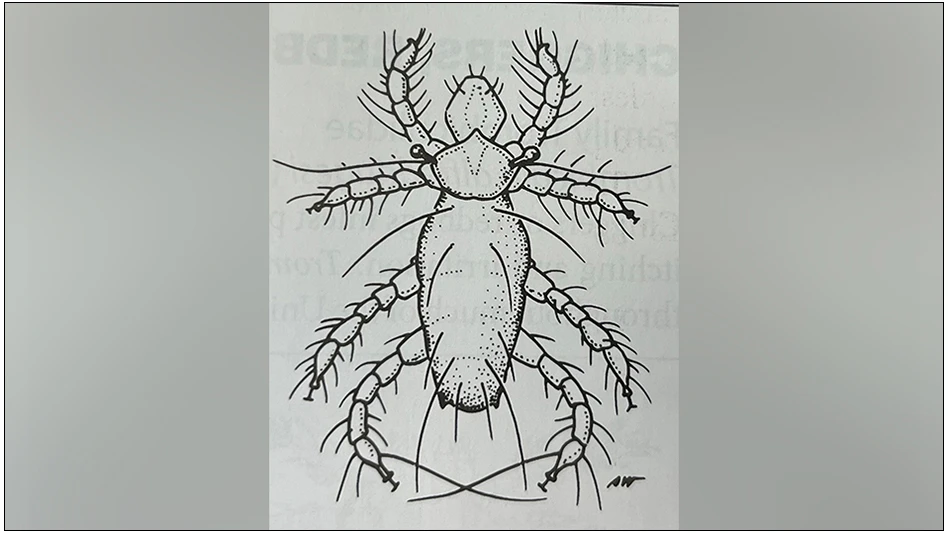

Cryonite kills all stages of roaches — from egg to adult with direct contact. The key to success with Cryonite is that it MUST make direct contact with the insect to work. This is where our old friend, spatial/forced monitoring comes into play.

Why Spatial Monitoring? Since Cryonite leaves no residue and only works on direct contact, you could spend your time guessing where the problem areas are or spraying everything, hoping to get lucky — or you can perform a spatial monitoring and create a map that shows you exactly where your target areas are. It doesn’t take any fancy equipment (not even a computer), saves you hours of field time and always works. Here’s how we used spatial monitoring and Cryonite in a roach program at a USDA-inspected, meat-processing plant.

The facility is a small meat-processing plant that packs bacon, sausage and smoked meats. It is a free-standing location that has continuously operated for more than 70 years. The building consists of numerous additions and sections pieced together to form the plant. The areas selected for the Cryonite testing were the employee locker room, as well as a break and dining area joined to the east side of the main facility. Construction is a wood frame central wall and then concrete block construction for the locker room walls and the exterior walls. The roof area is wood frame with a metal roof. This 1,764-square-foot area has a history of German roach infestations.

The author used a fully equipped Cryonite unit (bottom left) to treat a meat-processing facility. The work involved, among other tasks, treating a gap near the ceiling (top) and the use of ramped monitors (bottom right) to map current levels of infestation. The author used a fully equipped Cryonite unit (bottom left) to treat a meat-processing facility. The work involved, among other tasks, treating a gap near the ceiling (top) and the use of ramped monitors (bottom right) to map current levels of infestation. |

The area to be treated was determined by asking on the initial site visit “the” question: Where was the last place you saw the roach?

On the agreed upon date, at the close of business activity, 40 ramped roach monitors were placed to map current levels of infestation. Monitor distribution was floor to ceiling so all potential harborage areas could be identified. Each monitor was placed, identified and notated according to spatial monitoring protocol. All were picked up the next morning before the start of business activity.

After recording the number and type of roaches captured in each trap and trap placement, the harborage zones were located. A total of 49 roaches were captured in 8 of the 40 monitors. An additional seven roaches were located during an examination of the harborage zones. All these areas were documented on the site map to be treated with the Cryonite machine.

Treatment by two PCOs took place that day in the evening after close of business. The three rooms were treated with a crack and crevice style application to all areas of the space that could be reached. One-and-a-half 20-pound tanks of CO2 were used. No additional German roaches were seen during this process.

Due to the cleaning schedule of the facility, the post treatment site monitoring was conducted with a trap placement three days later, after the close of business. The devices were left in place during a routine weekend shut down until 6 a.m. (prior to the resumption of business) when they were collected and assessed. No roaches were captured. In addition, a visual assessment of the area produced no sightings. The Cryonite application removed the infestation. No insecticides were applied during the assessment or testing periods. The only interventions were glueboards for the purpose of verification and site mapping and the Cryonite for treatment.

Several areas of the facility were treated with Cryonite, including an employee locker room. Several areas of the facility were treated with Cryonite, including an employee locker room. |

So now we have a non-resistant one-two knockout punch to roaches. The first punch, spatial monitoring, maximizes time, effort and effectiveness to target where they hide. The second punch is a Cryonite treatment to kill them on contact. It’s a chemical-free treatment and can be used in places chemicals can’t go. How cool is that?

Author’s acknowledgements: Special thanks to Dr. Jeffrey Brown and the American Academy of Entomological Sciences for helping to make this project possible. Thanks also to Chris Buckaloo, manager of the Gainesville, Fla, Orkin office, who spent many hours in the field with us. For information on Cryonite visit www.cryonite.com.

Kate McGovern is CEO of The Resource Shop; Jeff McGovern is a pest management consultant; and Jeffrey Brown is director general of the American Academy of Entomological Sciences. They can be reached at jmcgovern@giemedia.com.

Spatial/Forced Monitoring Basics 1. Establish a date and time with the client, allowing at least six to eight hours minimum read time. Overnight works well and over the weekend in a closed facility is even better. Make sure the client doesn’t do anything special to clean or prep for your visit. We want the roaches at their best, which means to keep it as normal as possible.

4. Dropping and mapping occurs at the end of business activity at the site. As a trap is removed from the bag, it is given a number and location on its top with the Sharpie. Location refers to the height at which the trap is placed: 1 = floor to waist 2 = waist to ceiling 3 = above ceiling Example: 1-2 would be trap #1 and it was placed somewhere between waist high and ceiling. Place the traps and indicate the number and location on the map. Work one bag of traps at a time. If more than one person is placing, make sure they know the numbering sequence for their bag. Leave the facility after making arrangements for pick up before the start of business.

M = 12 feet F = 6 feet N = 12 inches FE = 12 inches Think of these distances as “bubbles” around the trap. With this map, you will be able to see the population distribution and accurately pinpoint harborage areas.

|

Explore the July 2012 Issue

Check out more from this issue and find your next story to read.

Latest from Pest Control Technology

- Target Specialty Products Expands Sales Leadership Team

- FORSHAW Announces Julie Fogg as Core Account Manager in Georgia, Tennessee

- Envu Introduces Two New Innovations to its Pest Management Portfolio

- Gov. Brian Kemp Proclaimed April as Pest Control Month

- Los Angeles Ranks No. 1 on Terminix's Annual List of Top Mosquito Cities

- Kwik Kill Pest Control's Neerland on PWIPM Involvement, Second-Generation PCO

- NPMA Announces Unlimited Job Postings for Members

- Webinar: Employee Incentives — Going Beyond the Annual Raise