A fly in the soup, literally not figuratively, is not a good thing for commercial food operations and their customers. The risk of flies transmitting food-borne illness is of major concern as is the damage the restaurant or food-processing facility would suffer to its brand, in lost revenue and possible regulatory action from local, state or federal agencies.

A fly in the soup, literally not figuratively, is not a good thing for commercial food operations and their customers. The risk of flies transmitting food-borne illness is of major concern as is the damage the restaurant or food-processing facility would suffer to its brand, in lost revenue and possible regulatory action from local, state or federal agencies.

Controlling flies in commercial kitchens and food-processing facilities has long been both a challenge and opportunity for pest management professionals. The challenge is preventing or eliminating aggressive flies from the facility and the opportunity is securing a long-term customer when you are able to swat flies from the account for good.

Nisus Corporation and NPD Products have teamed up to help pest professionals take advantage of the opportunities flies present by offering the TrueTech system. The system features NPD’s durable, high-performing foaming machines paired with Nisus’ product line for an effective solution to small fly infestations.

“We have been working with Michael Howe for many years handling the sales and marketing for his ProFoam Platinum foaming product and with the significant investment Michael makes in R&D we felt there could be great synergy if both companies worked together to build the TrueTech brand,” says Kevin Kirkland, CEO of Nisus Corporation.

Kirkland says Nisus was able to assist NPD with financial backing to support increased production and buying power, as well as offer expanded branding and marketing opportunities.

How will the relationship benefit pest management professionals tasked with eliminating a tough small fly infestation in a commercial kitchen? “The real benefit to PMPs is the ability to use a single piece of equipment to do a liquid spray, dry foam, wet foam and misting simply by connecting to different nozzles on the unit and using different attachments,” says Kirkland.

Kirkland adds that technicians previously could only foam around the top of the drain but with the TrueTech system they can easily apply Nibor-D foam 20 to 30 feet down the drain if needed to attack the source of the infestation.

Another feature for the PMP is that other than the compressor there are no moving parts in the units so there is far less chance of the equipment breaking down, resulting in lost service time and revenue.

Lee Barrett, division vice president, domestic/international pest control for Nisus, says technicians will be able to do more with less when it comes to the equipment they carry in their service vehicle.

“The TrueTech system gives technicians the flexibility to apply pesticides as a liquid, dry foam or wet foam from one machine and that fits nicely with today’s universal technician who is asked to service a variety of accounts in a day,” says Barrett. “It will make the technician more efficient on-site for the customer and give them the ability to treat deep down into the drain and reduce callbacks.

Technicians use the machine’s foam application tip to apply the foam directly into the drain, coating the surface areas of the drain and leaving a residual that will kill flies feeding or looking to establish harborage on the scum layer.

“This is not a Band-Aid approach to fly management but rather a proven method to eliminate flies,” says Barrett. “Combined with good sanitation protocols it gives them an effective fly control to market to customers.

“Additionally, even on accounts that can’t or won’t do the necessary santization, we are seeing PMPs getting control with this system,” Barrett said.

|

Foaming Over With Effectiveness The joint marketing effort of Nisus Corporation and NPD Products provides pest management professionals with a lineup of effective tools for their fly management toolbox. The TrueTech sprayer-foamer-mister allows PMPs to apply a solution of ProFoam Platinum with Nisus’ Nibor-D to prevent small fly build-up and infestations in and around drains in commercial kitchens and food-processing facilities. Using the machine’s foam application tip, technicians can apply the foam directly into the drain, coating the surface areas of the drain and leaving a residual that will kill flies feeding or looking to establish harborage on the scum layer. “Pest management professionals using ProFoam Platinum with Nibor-D are able to push it all the way through the pipes to reach drain and fruit fly harborage areas deep in the drain,” says Jim Gorman, corporate vice president of marketing for Nisus Corporation.

TrueTech 1000 — Good for dry and wet foam, and liquid applications, this versatile unit has a 1-gallon tank and allows technicians to make targeted applications in gallery and void areas, below-grade and under-slab areas, and interior and exterior applications. TrueTech 2000 — The 2-gallon version of this sprayer-foamer-mister comes with three foam tips, a 60-inch connection hose with palm gun and an extension wand that reaches from 24 to 44 inches to treat hard-to-reach areas behind large equipment or in tight spaces. TrueTech 2000 Power Cart — With a 2-gallon tank with its own compressor fitted on a utility cart, this unit is ideally suited to allow technicians to treat for a variety of pests including ants, flies and termites. In addition to 60-inch connection hose and multiple lengths extension wand, the unit includes a 15-foot extension hose. The TrueTech line is designed to deliver foam applications with targeted efficiency and leave a smaller environmental footprint. Features include:

Source: Nisus Corporation, www.nisuscorp.com |

A Proven Solution.

When Jim Tomlinson, lead technician for Perfection Pest Control in Union, Ky., walked into a commercial bakery account he was taken aback by the severity of the drain and fruit fly infestations that were present.

Tomlinson says fruit flies had infested two floor drains near a large mixing machine and the combination of food debris, including generous amounts of yeast and moisture, created an attractive harborage for the flies.

The location, which serves as the main production facility for the bakery’s retail outlets, is housed in an older building that contains numerous voids and structural challenges that are conducive to pest harborage. Add to that tons of unprocessed food ingredients and abundant moisture sources, and you have a recipe for potential pest problems.

“The build-up of debris in the drains had taken place over a period of time and with the facility operating six days per week sanitation wasn’t always done in a timely fashion,” says Tomlinson. “It reinforced the importance of working with customers to help them develop and follow good sanitation protocols.”

Tomlinson made some quick knockdown applications and cleaned the drain with bioremediation foam, but he had little success getting the large fly population under control. He then remembered sitting in on a demonstration that Nisus Area Sales Manager Harry Bryan had given on the TrueTech system with Nibor-D foam and thought it was worth a try.

Within two weeks after Tomlinson applied the Nibor-D foam into the drains he saw results and a big reduction in the fly population. “We service the account every two weeks and have to stay on top of it, but the results we had using the TrueTech system were very pleasing to us as well as the customer,” he said.

Tomlinson credits the TrueTech System’s flexible application tips and ability to leave behind a foam application that sticks deep down on the drain walls as the reason he was able to gain control of the large fly populations.

“It was the first time we used the system and because of its ease-of-use and the results we achieved, we will certainly look at using it in other accounts with tough fly infestations,” Tomlinson added.

|

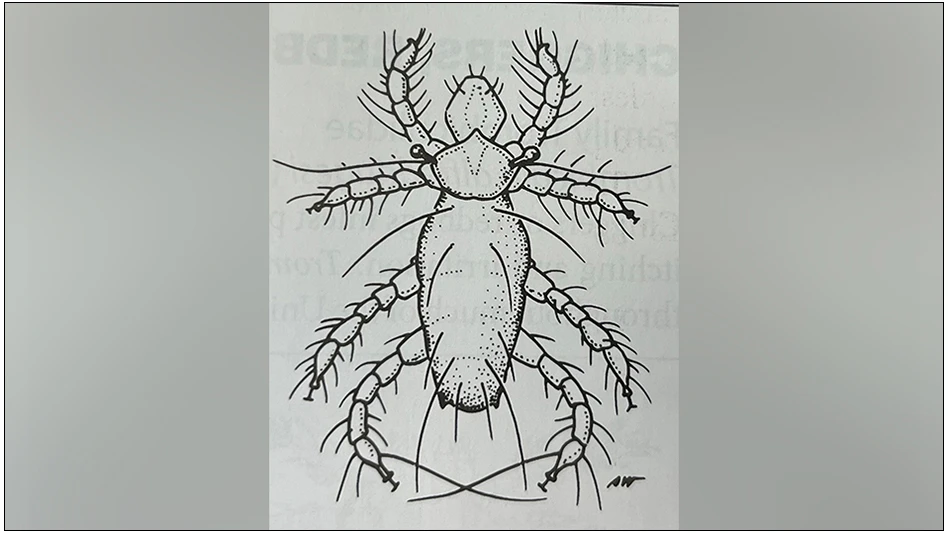

Small Flies = Big Problems Drain and fruit flies in commercial kitchens and food-processing facilities might be small in stature but they present big problems for facility managers. Among other things, flies are are capable transferring harmful bacteria on food, kitchen counters and food-preparation surfaces after feeding on waste materials. Drain and fruit flies breed in stagnant liquid that builds up in clogged drains and garbage containers. Adults are not great fliers and will hover in large numbers in and around their breeding location. Proper cleaning of the drain — all the way to the drain trap where food materials and waste materials can build up — and maintaining good sanitation protocols are essential to prevent flies from establishing a breeding site. Bioremediation and targeted pesticide treatments of the drain will eliminate drain and fruit flies. Drain Fly 411 Fruit Fly 411 |

The author is a partner of B Communications, an integrated communications/marketing firm. Email him at jfenner@giemedia.com.

Explore the July 2014 Issue

Check out more from this issue and find your next story to read.

Latest from Pest Control Technology

- Target Specialty Products, MGK Partner for Mosquito Webinar

- Cockroach Control and Asthma

- FORSHAW Announces Julie Fogg as Core Account Manager in Georgia, Tennessee

- Envu Introduces Two New Innovations to its Pest Management Portfolio

- Gov. Brian Kemp Proclaimed April as Pest Control Month

- Los Angeles Ranks No. 1 on Terminix's Annual List of Top Mosquito Cities

- Kwik Kill Pest Control's Neerland on PWIPM Involvement, Second-Generation PCO

- NPMA Announces Unlimited Job Postings for Members

The lineup of tools includes the following units:

The lineup of tools includes the following units: